Torque and Tensioning Equipment

Power Products Sales and Service, Inc. is one of the leading companies in controlled fastening technology and hydraulics all over North America. We strive to reduce costs and uncertainty when decoupling and doing this in the most effective, productive, and sustainable way. We offer a wide variety of tensioning equipment, full on-site machining services, portable and in-place machining equipment, heat-treating equipment, turbines, boiler and heat exchanger tools, and equipment to the energy and heavy industry for over 25 years and have 60 years of experience in hydraulic bolting and coupling solutions.

For more questions and inquiries about our products and services, don’t hesitate to give us a call or email us. We are here to help, talk to the expert today.

Our Products

Torque and Tensioning

Downloads:

- Pilgrim in Brief.pdf

- RSLBrochureMain.pdf

- TENTEC MST Data sheet R3 A4.pdf

- marine brochure_2011.pdf

- Hydro Cam PIL_PRO_015_0719_EN.pdf

- powerbrochure.pdf

- RAD-Catalogue-Imperial_Online_Final_July2017.pdf

- MicroMAX-Battery-Pump.pdf

Pilgrim in Brief

Why and What

As the World Leader in Controlled Fastening Technology and Hydraulics, Pilgrim strives to reduce your costs and uncertainty when decoupling. Doing this in the most effective, productive and sustainable way contributes to our vision of “A World of Trouble Free Decoupling”.

How

- With over 60 years experience in hydraulic bolting and coupling solutions

- A committed and highly knowledgeable workforce

- ISO 9001 2015 and ISO 14001/OHSAS 18001 accreditations

- Extensive customer application experience and reference lists

Pnuematic Tools

Downloads

ATP Industrial Pneumatic Tools & Chipping Hammers

FEATURES OF ATP PROFESSIONAL TOOLS

- Alloy steel hammer cases machined from solid bar not drawn or cast.

- Model number stamped in motor housing under the name plate for permanent identification.

- High power to weight ratio.

- 100% parts interchangeability to the equivalent tool.

- Your replacement parts inventory will work for any tool you purchase.

- 100% American Made.

| TWIN HAMMER SERIES Steel clutch housing… 3 piece housing construction for ease of maintenance… pressure feed lubrication for impact mechanism…built in oil lubricator for air motor…available in #5 spline or square drive…adjustable power regulator for forward and reverse power control…ergonomic handle… exhaust with sound reducing muffler |

|

| BALL AND CAM SERIES Precision ball and cam mechanism converts air motor torque into powerful rotary impacts… a time-tested design for maximum durability…ideal for soft joint applications |

|

| TWO JAW CLUTCH SERIES High energy per blow for maximum performance…rugged steel clutch housing, 3 piece housing construction for ease of maintenance…sound reducing muffler, available in #5 spline and square drive with either inside or outside throttle…assist handle is standard, D Handle-optional on 1011 and 1520 |

FEATURES OF ATP PROFESSIONAL TOOLS

Alloy steel hammer cases machined from solid bar not drawn or cast.

Model number stamped in motor housing under the name plate for permanent identification.

High power to weight ratio.

100% parts interchangeability to the equivalent tool.

Your replacement parts inventory will work for any tool you purchase.

100% American Made.

TWIN HAMMER SERIES

Steel clutch housing… 3 piece housing construction for ease of maintenance… pressure feed lubrication for impact mechanism…built in oil lubricator for air motor…available in #5 spline or square drive…adjustable power regulator for forward and reverse power control…ergonomic handle… exhaust with sound reducing muffler

BALL AND CAM SERIES

Precision ball and cam mechanism converts air motor torque into powerful rotary impacts… a time-tested design for maximum durability…ideal for soft joint applications

TWO JAW CLUTCH SERIES

High energy per blow for maximum performance…rugged steel clutch housing, 3 piece housing construction for ease of maintenance…sound reducing muffler, available in #5 spline and square drive with either inside or outside throttle…assist handle is standard, D Handle-optional on 1011 and 1520

Mactech In Place Machining and Onsite Services

Clamshells A complete line of patented clams for pipe cutting, pipe beveling, ID boring, facing and OD turning.

BU Flange Facer An entire range of inexpensive pipe beveling tools for re-facing flanges.

End Prep Machines Adjustable for various pipe beveling and flange facing configurations.

Oval Manway Seat Grinder Conditions old and corroded gasket oval manway seat grinder surfaces.

Hand Hole Grinder Used for repairing and refurbishing leaking hand hole surfaces.

Tire Grinder This stationary machine is designed to regrind tires, trunions and rollers on kilns and large vessels.

Trunnion-Grinder This portable grinding machine provides powerful and accurate on-site grinding for trunnions or other large rollers.

Portable Milling Machines Single or all axis precision machining done accurately and quickly with these portable mills.

Keyway Cutters Re-cuts worn keyways or new keyways in place.

Portable Hydraulic Drill Versatile and portable machine for drilling, tapping, core-drilling and line boring.

Portable Boring Bars A variety of boring tools for smooth and precise portable boring.

Journal Turning Lathe Smooth and accurate in-place machining of journals and shafts.

MS-JTL The new MS-JTL combines our Clamshell and Journal Turning Lathe designs for precision machining of large diameter shafts.

Axial Feed Adaptable to our Clamshell Machine, it is designed to meet crucial specifications of weld finishing and OD turning in limited space and hostile environments.

Hydraulic Power Supplies Self contained units capable of supplying power to all the hydraulic equipment.

Tube Specialty Tools Complete line-up of precise tube squaring and tube cutting tools for High Purity Piping Technology.

Boiler Tooling

![]()

Bevel, square and perform other standard and custom end prep projects quickly and safely with high quality H&S Tool products.

H&S offers innovative solutions to tube, pipe beveling, machining for end prep challenges. Conventional and high speed models make tough milling jobs safe and easy. Conventional models feature internal locking for maximum safety and accuracy in tube, pipe beveling machining projects.

Single tube, hand-held saws and track-mounted abrasive wheel saws make short work of small tube replacement and large waterwall panel removal.

High quality tube rolling/expanding tools feature automatic torque control for maximum sealing and accuracy. Pulling equipment is also available.

Whether you are doing end prep tube, pipe beveling machining, these boiler tube tools are perfect for boiler repair in power generation plants, performing maintenance in oil, gas and petrochemical processing and distribution plants or a tube and pipe fabricating company — H&S has a large inventory of tools for rental or purchase for fast delivery.

The quality and service in tube, pipe beveling machining end prep tools will give you a competitive edge for all types of tube and pipe work.

Welding Tools

![]()

Power Products has specialty tools that you need for your all specific welding needs.

Weld Head Chart – click on the link to see what OD and wall thickness each weld head applies to.

Tube Weld Heads (Fusion)

C-Heads

C-10 – Models 809B & 819 – 6.4mm-25.4mm (0.25in-1.0in) OD

C-25 – Models 811B & 821 – 12.7mm-63.5mm (0.5in-2.5in) OD

C-35 – Models 812B & 822 – 19.1mm-88.9mm (0.75in-3.5in) OD

C-45 – Models 813C & 823 – 25.4mm-114.3mm (1.0in-4.5in) OD

Tube/Pipe Weld Heads (Fusion/Filler Wire)

R-Heads

R-1 – Model 413 & 427 – 12.7mm-38.1mm (0.5in-1.5in) OD

R-2 – Model 414 & 428 – 33.4mm-88.9mm (1.315in-3.5in) OD

R-3 – Model 415 & 429 – 88.9mm-168.3mm (3.5in-6.625in) OD

E-Head – Model 421 & 441 – 25.4mm-355.6mm (1.0in-14.0in) OD

Pipe Weld Heads (“Full Function”)

Quickclamp – Model 432 – 25.4mm-88.9mm (1.0in-3.5in) OD

D-Head

Quickclamp – Model 433 – 60.3mm-168.3mm (2.375in-6.625in) OD

D-Head – Model 420 – 25.4mm-355.6mm (1.0in-14.0in) OD

T-Head – Model 417A & 418 – 168.3mm&up (6.625in&up) OD

T-Head “Narrow Gap” – Model 416 – 168.3mm&up (6.625in&up) OD/ID

Tube-to-Tubesheet Weld Heads

424 Tubesheet Head – Model 424 – 10mm-78mm (0.4in-3.07in) OD

425 Tubesheet Head – Model 425 – 10mm-140mm (0.4in-5.52in) OD

426 Tubesheet Head – Model 426 – 10mm-70mm (0.4in-2.76in) OD

GMAW/FCAW Pipe Weld Head

Tubesheet Heads

Pipeliner II – Model 609A – 168.3mm&up (6.625in&up) OD/ID

Tube, Tube/Pipe, & Tube-to-Tubesheet Power Source/Controllers

Tubemaster – Model 514 – Digital – 200Amp

Tubemaster – Model 512 – Microprocessor – 300Amp

Tubemaster – Model 522 – Analog – 300Amp

Tubemaster Model 514

Pipemaster – Model 510 – Microprocessor

Pipemaster – Model 515 – Digital – Coming Soon

Pipe master – Model 520 – Analog

Pipe Power Source/Controllers

Pipemaster – Model 510 – Microprocessor

Pipemaster – Model 515 – Digital – Coming Soon

Pipemaster – Model 520 – Analog

GMAW/FCAW Pipe Power Source/Controllers

MPS4000 – Model 712

The Autoweld® System

Pipemaster

Lincoln Electric STT Power Source & Magnatech Weld Head – Model 610A

Special Applications & Engineering

Control Rod Drive Mechanism (CRDM) Welding System

Pipeliner

Accessories and Options

Heavy Duty Water Cooler – Model 903

Water Cooler – Model 904

Dual Head Switcher

FLX-Track

Tilt AVC for D-Head – Model 420 & T-Head – Models 416, 417A, & 418

Induction Heating

![]()

Miller Induction Heating Systems are designed to simplify the process of preheating and stress relieving. The process provides uniform, rapid heating that improves weld quality and reduces operational costs. The equipment is simple to setup, use and operate.

This non-contact method of heating is operator friendly and lowers consumable costs for insulation, fuel gases, or ceramic pads.

Literature

Induction Heating Systems:

Air Cooled Preheat Systems

Liquid Cooled Preheat and Stress Relieving Systems (pdf file)

System Components:

Intellifire 250 – 25kWPower Source

Intellifire 204 – 20kWPower Source

IHPS II – 5kW Power source

IH/PC Pendant Controller

Flexible Induction Blankets (pdf file)

Related Articles:

Time-to-Temperature Calculator (pdf file)

Turbine Tools

Downloads:

With over 20 years of service, Hesse Equipment Company has grown from a small family owned and operated company to a corporation serving customers in a wide variety of industries including Power Generation, Cement, Metals, Refining and Paper & Pulp. HEC currently does business in the U.S. and around the world providing specialty turbine tooling and expansion joints to utilities and repair companies alike.

As specialists in the science and manufacture of electric heat products, Heatrex serves an array of national and international customers. A team approach and commitment to Total Quality, combined with encouraged customer interaction, fosters a unique and effective environment for concept development, prototype design and testing, and manufacture of top-quality products.

Purge Equipment

Downloads:

ARGWELD® Purge Bladders localize the purge area when welding long pipe sections. the savings in gas and man hours mean that these bladders pay for themselves with in a few welds.

ARGWELD® Purge Bladders

ARGWELD® Purge Monitors detect the level of oxygen in purging gas to indicate when it is at a safe level to weld. A range of monitors have been designed to cover every need

ARGWELD® Purge Monitors

ARGWELD® Water Soluble Film is used to localize the purge area in a large or irregular fabrications and can be used to make closing welds. The film is fully soluble and contains no harmful elements.

ARGWELD® Water Soluble Purge Film

ARGWELD® Trailing shields give a secondary shielding gas coverage which prevents the material from oxidizing following welding. This allows larger titanium fabrications to be welded outside of an enclosure.

ARGWELD® Trailing Shield

ARGWELD® Pipe Purging Plugs are used on smaller diameter and shorter length tube or ducting applications. These are also very useful for sealing outlets when purging vessels, as low pressure test plugs for pipe joints or to stop contaminants entering tubes.

ARGWELD® Pipe Purging Plugs

Borescopes

![]()

VS 10-4 Flexible Video Scope .394″ (10 mm) 4-way articulating video scope that delivers full color high resolution images of remote difficult to reach areas. Bend radius of 5.0″ -127 mm. Available in lengths up to 35′.

FS394 Flexible Fiberscope

.394″ (10 mm) 4-way articulating fiberscope that delivers high resolution images of remote, difficult to reach areas. Bend radius of 3.0″ – 76 mm. Available in lengths up to 120″.

FS350 Illuminated Flexible Viewer

.350″ (9 mm) designed to inspect hard to reach locations. This instrument uses high resolution imaging fiber to carry the image from the wide angle objective lens to the easy-to-view high magnification eyepiece. Standard length is 18″.

IG350 Flexible Viewer

.350″ (9 mm) designed to inspect hard to reach locations. This instrument uses high resolution imaging fiber to carry the image from the wide angle objective lens to the easy-to-view high magnification eyepiece. Requires external light source at viewing end. Standard length is 17″.

FS315 Flexible Fiberscope

.315 (8 mm) 4-way articulating fiberscope that delivers high resolution images of remote, difficult to reach areas. Bend radius of 2.75″ – 70 mm. Available in lengths up to 120″.

FS312 General Purpose Fiberscope

.312″ (7.9 mm) self-contained, versatile inspection device to detect worn, damaged or otherwise inadequate conditions in hidden or normally inaccessible areas. Standard length of 24″.

FS276 General Purpose Fiberscope

.276″ (7 mm) 2-way articulating fiberscope that can be used in many preventative maintenance inspection programs. Bend radius of 1.5″ – 38 mm. Available in different lengths. Standard lengths are 24″ and 36″.

FS236 Flexible Fiberscope

.236″ (6 mm) 2-way articulating fiberscope that can be used in many preventative maintenance inspection programs. Bend radius of 2.0″ – 50mm. Available in lengths up to 120″.

FS140 Flexible Fiberscope

.140″ (3.5 mm) 2-way articulating fiberscope that can be used in many preventative maintenance inspection programs. Bend radius of 1.5″ – 38 mm. Available in different lengths. Standard lengths are 24″ and 36″.

FS120 Fiberscope

.120″ (3 mm) portable, rugged inspection device capable of producing a high resolution image of critical components through access holes as small as 3.0 mm. Available in lengths up to 72″.

FSR078 Microborescope

.078″ (2.0 mm) portable, rugged inspection device capable of producing a high resolution image of critical components through access holes as small as 2.0 mm. Standard length is 6″ and 12″.

FS066 Microborescope

.066″ (1.68 mm) portable inspection device capable of producing a high resolution image of critical components through acces holes as small as 1.7 mm. Standard length is 6″ and 12″.

FSR039 Microborescope .039″ (1.0 mm) portable inspection device capable of producing a high resolution image of critical components through access holes as small as 1.0 mm. Standard length is 6″ and 12″.

Morgrip Pipe Connectors and QUICKFLANGE™

Downloads:

MORGRIP® is a weldless mechanical connector which provides a high integrity connection for all types of metal pipework, onshore and offshore, topside and subsea.

MORGRIP® onshore and topside connectors are designed to be used as a firesafe weldless replacement for a permanent pipeline repair, blanking redundant lines or for tie-ins. MORGRIP® is faster and safer to complete than a weld and being a mechanical connection does not require a hotwork permit. Two standard ranges are available, often from stock for popular pipe sizes:

The 150 Series range, for pipelines of ANSI 150lb pressure rating,

The 2000 Series, for up to ANSI 1500lb pressure rating.

Lloyds Register and DnV Product Approvals permit designs to supplied up to ANSI 2500lb, although these are not normally stocked.

MORGRIP® subsea connectors are used for repair of existing pipelines, routing modifications or tie-ins. The connector replaces a weld or other mechanical connections.

The QUICKFLANGE™ is a standard range of pipe to flange connectors terminating in an ANSI 900lb rated weld neck flange. Other designs, ratings and terminations can be quickly configured to suit customer specifications.

All connectors can be supplied with certification for compliance with your chosen pipeline code including the recent DnV RP-F104 Recommended Practice for Pipeline Connectors.

Hydratight Sweeney also design 3000 series bare pipe to bare pipe couplings for use with divers and 3000Ri couplings for deeper water for use with ROV vehicles.

To assist design, project, or construction engineers two selection software programs are available free of charge, one for topside or onshore, the second for subsea. Both programs provide key data including dimensions and weights.

Quickflange

Features

Quickflange from MORGRIP® is the high specification pipeline connector used for permanent subsea and tie-in applications around the world.

With its successful MORGRIP® supply history of 1100 connectors, HYDRATIGHT SWEENEY now offers QUICKFLANGE™ which provides the benefits of MORGRIP® at a competitive price.

QUICKFLANGE™ employs patented and unique weld-strength grip and metal/graphite sealing systems in a connector simplified for easy installation.

Benefits

- Compliance with API 6H

- DNV Type Approved up to 42” and 2500lb (in accordance with RP-F104)

- Lloyds Register Approval – all sizes and pressure ratings

- QUICKFLANGE™ metal seals compliment those of ball flanges and RTJ flanges

- Out-performs 9/10 welds in terms of fatigue

- Design life life of 30 years

- Easily installed by customer personnel

Stress Relieving Equipment and Furnaces

Downloads:

COOPERK9

|

COOPER36

|

Boiler Tube Alignment

Haywood Machine manufactures boiler tube alignment clamps and waterwall panel jacking devices.

Tube Alignment Clamps

|

“A” Model Clamp – used on a 1-1/4″ water wall tube panel.

“A” model clamps fit 7/8″ OD through 1-3/4″ OD tubes. |

|

“B” Model Clamp

“B” model clamps fit 1-1/2″ OD through 2-1/2″ OD tubes. |

|

“S” Model Clamp

Special Clamps that are short on one end can be used where obstruction such as a header, bend or swedge prevents the use of a normal clamp. |

|

Tig Welding a waterwall tube.

Over 50% of the root pass can be welded without removing the tube clamp. Without having to tack weld the tube first, one side of the tube can be welded with only one tie in. This will greatly reduce the chances of a rejected radiograph for incomplete or excessive penetration. |

|

“B” Model with 2-1/2″ tubeJacking screws on all clamps help to align tubes when there are differences in the outside diameter, such as worn, pitted or overlayed and pad welded areas. |

|

Ratchet wrenches can be supplied if requested. |

|

There are currently 2 sizes of Boiler Tube Alignment Clamps available for rent.

These clamps are supplied with Custom made, Heat Treated Alloy U-bolts. When ordering please specify OD of tubing and width of membrane if Clamps are to be used on waterwall tubes. 2 ea. – U-bolts with extra nuts and washers are supplied with each clamp at no extra cost. Order as many U-bolts as you think will be needed for the job, there is no charge for U-bolts that are returned in unused condition. Ratchet Wrenches or ½” drive deep well sockets ( 11/16” ) can be supplied if requested. |

Waterwall Panel Jacking Devices

|

Waterwall Panel Jacking Device

This jacking device is used to align waterwall panels or plates and beams. It has 10 tons of force. |

|

Aligning 1 1/4″ tube Waterwall panels |

|

Aligning 1 1/4″ tube Waterwall panels |

|

Weld on lug for Jacking Device

These lugs can be ordered for any size tubing and can be reused many times. |

|

Panel Jacking Equipment

There are currently 2 sizes of Panel Jacks available for rent.

They both have the same amount of jacking force and have been tested at the full capacity of the Porta Power cylinder ( 10 Tons). When ordering weld on lugs for the Panel Jacks, please specify whether the jacks will be used for plates/beams or waterwall tubes, the OD of the tubing & membrane width is needed for the proper lug length. These 2 hole lugs can be reused many times. |

Product Applications

These are shots of a hydraulic nut removing coupling bolts on a 300 mega watt water wheel turbine. The customer used to take two days to remove these studs with the hydraulic puller the accomplished it in one shift.

Pipe Plugs

Downloads:

COB Industries Inc, has a pipe plug/ test plug for almost every application. From 1/2″ to 96″ diameters and 0 PSI to 10,000 PSI, COB can answer all of your pipe plug needs. Multi-sized inflatable pipe plugs will cover a broad range of pipe sizes with a single plug. Bag Plugs provide a foreign material or gas barrier for many different pipe applications. Our mechanical wing nut style pipe plugs offer an economical way to block off or test low pressure applications through 36″ in diameter. Wing nut style plugs are available in chemically resistant nylon 6 material as well as aluminum bodies.

Custom made units are made from virtually any material for temperature or chemical resistance. The Qwik Sealfast pipe test plugs provide an additional level of security when testing up to 96″ diameter pipe with their internal bracing lugs. Medium Pressure Roll-Ups use an inflatable seal around a solid core to give up to 150 PSI back pressure capabilities. Disc plugs allow for testing to 15 PSI in limited distance applications. Viton, Silicon and Nitrile seals are available to chemical and high temperature applications. If we don’t have it in stock you can be sure we probably made it before and can quickly and efficiently make any plug plugs or test plugs for your application.

- Nylon Expansion Plugs

- Aluminum Expansion Plugs

- Bag Plugs

- Qwik Fit Cylinder Plug

- Qwik Test Seal Plug

- External Closure

- High Pressure Stopper

- OLS

- Flex ODS

- MegaPlug

- Sealfast

- Medium Pressure Roll-Up

- Chemical Resistant Plug

- ATO Pipe Stopper

Pipe Freezing Equipment

Downloads:

QWIK-FREEZER™

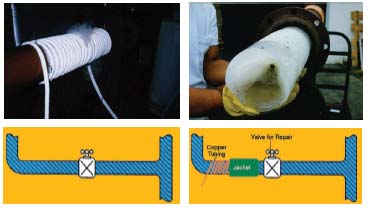

Qwik Freezer equipment utilizes liquid carbon dioxide (CO2) to freeze stationary water in selected sections of pipe or tubing. By producing very low “dry ice” temperatures, Qwik Freezer forms a secure in-line ice plug. This temporarily isolates the water in the system and allows repairs or modifications to be made without draining down or shutting off systems.

Qwik Freezer® equipment utilizes liquid carbon dioxide (CO2) to freeze stationary water in selected sections of pipe or tubing. By producing very low “dry ice” temperatures, Qwik Freezer® forms a secure in-line ice plug. This temporarily isolates the water in the system and allows pipe repairs or modifications to be made without draining down or shutting off systems.

The Qwik Freezer® kit is easy to use. A specially designed jacket is wrapped around the pipe at the point where the freeze is required. A nozzle on the jacket is then coupled to a cylinder of liquid CO2 by means of a high pressure hose. When the liquid CO2 is injected into the space between the jacket and pipe, it immediately expands to form a solid carbon dioxide (dry ice) at a temperature of -109ºF (-78ºC). This low temperature quickly freezes the contents forming a secure “ice plug” which seals the pipe.

The “ice plug forms only in a section of pipe covered by the jacket so the resulting rise in pressure is very small and there is no damage to the pipe. The technique can be used safely on iron, lead, stainless steel, copper, brass and plastic pipe.

Major Advantages

- Saves valuable time normally lost in draining down and refilling a system.

- Avoids complete shutdown of systems and equipment (as in a sprinkler or water supply system)

- Prevents waste of large amounts of water.

- Eliminates handling of waste water.

- Safe and cost effective.

FOR USE IN MANY INDUSTRIES

- Office & Commercial Buildings

- Petro/ Chemical Refineries

- Food & Beverage Plants.

- Municipalities.

- Hospitals/Nursing Homes

- Industrial Plants

- Water Treatment Facilities

- Conventional & Nuclear Power Plants

- Residentia

- Restaurants

- Ships

- Schools/Universities

- Hotels/Motels

- Water Utilities

- Aerospace.

Qwik Freezer kits consist of insulating pipe jackets, CO2 cylinder(s), reinforced high pressure hose, fittings, insulated work gloves, a rubber mallet, safety glasses, operating manual, timing log and carrying.

CO2 CYLINDER

COB provides specially adapted liquid CO2 cylinders for use with Qwik-Freezer equipment. The COB QFAL20, a 20 pound aluminum cylinder with protective handle, is supplied with 3/8″ to 3″ kits. A 50 pound aluminum cylinder, QFAL50, is supplied with 4″-8″ kits as standard equipment. CO2 cylinders can be filled by local welding and carbonic distributors.

Qwik-Freezer Jackets

- QF101 for 3/8″ (9.375 mm.) to 3/4″ (18.75 mm.) Pipe size.

- QF 102 for 3/4″ (18.75 mm.) to 1-1/2″ (37.5 mm.) Pipe size.

- QF103 for 1-1/2″ (37.5 mm.) to 3″ (75 mm.) Pipe size.

- QF104 for 3-1/2″ (87.5 mm.) to 4″ (100 mm.) Pipe size.

- QF106 for 5″ (125 mm.) to 6″ (150 mm.) Pipe size.

- QF108 for 7″ (175″ (175 mm.) to 8″ (200mm.) Pipe size.

ACCU-FREEZE

Accu-Freeze utilizes liquid nitrogen in a controlled system to freeze stationary liquids in a selected section of pipe or tubing. By controlling the surface temperature of the pipe, Accu-freeze can accurately and safely form an in-line ice plug, capable of withstanding 2000 psi in pipes up to 12 inch diameter.

Accu-Freeze utilizes liquid nitrogen in a controlled system to freeze stationary liquids in a selected section of pipe or tubing. By controlling the surface temperature of the pipe, Accu-freeze can accurately and safely form an in-line ice plug, capable of withstanding 2000 psi in pipes up to 12 inch diameter. This temporary plug isolates the section, thus allowing repairs and modifications to be made without shutting off or draining down the entire system.

The Accu-Freeze Technique

Throughout Qwik-Freezer’s twenty-five years of pipe freezing and maintenance our customers have requested pipe-freezing systems that will:

- Be able to freeze larger diameter pipe

- Control the entire freeze process

In response to this COB Industries, Inc. introduces Accu-Freeze the world’s first controlled liquid nitrogen pipe freezing system. An Accu-Freeze ice plug starts with wrapping copper tubing and specially designed insulated jacket around the section of pipe to be frozen. The liquid nitrogen is supplied by your local welding or gas distributor. The nitrogen is then injected through our patent pending control system. By constantly reading the surface temperature of the pipe the Accu-Freeze system controls the flow of liquid nitrogen through the wrap and accurately and safely forms an ice plug in lines up to 12 inch diameter.

Accu-Freeze uses it patented control system to accurately and safely create an ice plug. The ice plug only forms beneath the Accu-Freeze coil wrap and jacket (jacket is used on a 6-12 inch pipe.) and does not expand outside of this point. This controlled plug does not create enough pressure to effect the integrity of the pipe. Pipe burst happen when ice forms in an uncontrolled manner and create hydrostatic pressure between ice plugs or against a closure in the line. (Care should be taken to freeze 12 inches away from any closure for every 1 inch diameter of pipe). If you should have any questions please consult a COB Freeze Technician.

Safety Notes

Accu-freeze utilizes liquid nitrogen to create the cryogenic temperatures necessary to form ice plugs. Safety precautions must always be taken when using this product.

Protective clothing, gloves, goggles etc. must be worn at all times when operating this product. Failure to do so may result in severe frostbite.

Liquid nitrogen is heavier than air and will displace oxygen. Proper ventilation is required especially when operating in confined areas.

Accu-Freeze is designed to operate with liquid nitrogen tanks fitted with 22 psi safety valves. Use with any tanks other than properly specified will cause damage to unit and possibly harm to the operator. Please consult a COB Technician for other pipe freezing or pipe repair information.

Hydraulic Torque wrench sockets and Slugging wrenches

Downloads:

ATP / OZAT “Less-Stress” Impact Wrench Sockets are clearly superior in design to most other sockets available today. Our state of the art Electro-Chemical Machining (ECM) process makes it possible for us to produce all of our Sockets in

the “Less-Stress” configuration.

ATP / OZAT Sockets are available in 1/2” through 3 1/2” Square Drive and in #4 and #5 Spline sizes, in 4 point, 6 point, 8 point, 12 point, Standard depth, Deep length, Thin walls, Hex bit, “In-Star” type bits, Magnetic bits, Rail Road sockets and Torsion bars.

Custom Sockets quoted upon request. OZAT marked sockets carry a “Life Time Warranty” against breakage.

Slugging Wrenches including:

- Flat striking wrenches

- Offset striking wrenches

- Torsion bars

- Quick change torsion bars

Pneumatic, Battery-Operated, and Electric Torque Wrenches

Downloads:

RAD® pneumatic torque wrenches are air powered planetary gear reduction torque multipliers designed to deliver the most powerful, accurate and safe torque load of any tools on the market today.

Our patented gearbox design allows us to configure very high gear ratios (up to 686:1) developing extremely high torque values from a lightweight and ergonomic hand held pistol grip tools. Rad Torque tools are being used Worldwide in many industries where power, durability and accuracy are considered critical.

Our smooth constant rotation drive system make our tools ideal for applications other than bolting fasteners such as valve actuation, hopper car door opening, running large threading taps, etc. RAD® pneumatic torque wrenches are regularly replacing more traditional bolting tools for safety reasons and cost effectiveness.

RAD® Pneumatic Torque Wrenches compared to Impact Wrenches

- No Vibration (virtually no operator strain)

- Very Low Noise Level, 80db @ full power (1″Impact 110 db)

- Very low operating cost, no hammering parts to wear out

- No Wear on sockets

RAD® Pneumatic Torque Wrenches compared to Hydraulic Wrenches

- Less than half the purchase price

- Much quieter to operate

- Much more portable than heavy and awkward hydraulic pump

- Many times faster operation to complete bolting task economically

- Fully reversible immediately, no drive and reaction arm to be changed

RAD 350SL |

RAD 350SL-2 |

RAD 550SL |

RAD 550SL-2 |

RAD 550NX |

RAD 550NX-2 |

RAD 800NG |

RAD 800NG-2 |

RAD800NGX |

RAD 800NGX-2 |

RAD1000SNX-2 |

RAD 1400NGX |

RAD 1400NG-2 |

RAD 1400NG |

RAD 1800NGX |

RAD 1800NG |

RAD 1800NG-2 |

RAD 30 |

RAD 30-2 |

|

FME Products

Safe-T-Sponges™

Safe-T-Sponges™ were developed because excluding machining chips and contamination from boiler tubes and pipes has been a recurring problem. Hand made “gags” were inconsistent, difficult to remove and hard to find on the job site.

|

We offer three different types of

|

Isolation Barriers

Downloads:

The manufacturer was approached by American Electric Power in 2002 regarding an interest in supplying them a heavy duty inflatable device to temporarily seal off an 18′ wide x 20′ high duct work in a large coal fired power plant.

Units that share a common stack often experience opacity excursions that are aerosols rather than particulates. These aerosols form when the stack flue gas temperature falls below the dew point temperature because of air in-leakage from out of service units, especially at reduced loads. Although zero leakage dampers are available, most units are not equipped with this type of damper. The plant personnel or their designated contractor will sometimes install barriers made of wood and plastic sheeting in order to effectively seal off this air in-leakage from the existing dampers. These temporary wood frame & plastic barriers are time and labor intensive to make, install and remove. These temporary barriers are usually discarded at the end of the outage.

The device is called a “duct balloon” which can be inserted upstream of a louvered damper and inflated to provide a temporary barrier inside the duct. The balloon is constructed out of a durable, acid resistant fabric, and can be reused outage after outage. The material is strong, lightweight, resistant to tears, and is rated to 485°F. Using the supplied 110V blower system, they inflate in 10 minutes or less. The balloon can be quickly deflated by opening a large zipper and it can collapses down small enough to fit through an existing man way allowing it to be removed from the duct work in minutes.

Past applications for using duct balloons are:

-

Isolating duct work during maintenance of ID fans

- Controlling fugitive dust during precipitator grit blasting

- Isolating duct work during catalyst element change out in SCR’s

- Isolate inlet duct work or exhaust stack on Gas Turbines with HRSG

- Isolate equipment from overspray during boiler water washing

- Temporarily sealing off the bottom of cyclones and hoppers during outages

- Isolating primary air ducts during pulverisor maintenance

Stud Cleaners and Bolt Cleaners

Downloads:

It’s finally here! A portable, purpose built machine that uses a patented brush system to clean even the dirtiest bolts and pipes – from 3/4″ to 3″ in diameter – faster, safer and cleaner than ever before. Developed through years of on-site and shop experience, the Shipman Industrial Bolt & Pipe Cleaner offers distinct advantages over traditional cleaning methods. Made in the USA, the Shipman Industrial Bolt & Pipe Cleaner takes the hard work out of a dirty job.

We’ve all been there. You know, standing in front of a screaming benchtop grinder with a dirty bolt or pipe – the sparks flying and your forearms aching from turning as you slowly erase the rust and sludge left behind by years of heavy use. Finally you finish, ignoring your sore back, stiff hands and raw skin covered with stinging , irritating metal filings. Then you pick up another piece and start all over again.

If this sounds all too familiar, don’t worry. You are not alone. Fact is no matter how you approach it, cleaning pipes and bolts has never been an easy job. The good news is that it doesn’t have to be that way any longer.

The Shipman Industrial Bolt & Pipe Cleaner takes the hard work out of a dirty job. Simply place any length of pipe or bolt into the machine’s powerful chuck and adjust the cleaning wheel diameter. Then flip the conveniently placed switch and guide the variable-speed power-assisted Servo® Drive. That’s it. Just watch as the Shipman’s patented brush system quickly and easily lifts years of grit and grime from even the dirtiest bolts or pipes and traps them in one small on-board collecting unit. Or connect it to your shop’s central vacuum unit. Either way, there are no more bits of sharp metal on your clothes, your skin or in your eyes. You’re left with an incredibly clean bolt or pipe that’s ready to coat or re-install. All in a fraction of the time it used to take!

Faster. The Shipman’s powerful motor, Servo® Drive and variable-speed power-assist cleans bolts and pipe and average of 90% percent faster, increasing productivity and reducing labor costs.

Safer. A shielded housing and automatic shut-off switch ensures the operator’s hands never come in contact with the machine’s wire brushes, reducing potential accidents and possible down time.

Cleaner. Designed for today’s environment consideration, the Shipman Industrial Bolt & Pipe Cleaner effectively “traps” the airborne pollutants normally found during the cleaning process and collects them in one small, easily discarded vacuum chamber. Best of all, it uses no messy chemicals.

At the same time, the Shipman’s patented brush system increases surface area contact, providing a cleaner end product. Plus, its durable frame, compact size and locking rolling casters allow you to take your Shipman machine wherever work calls.

Isn’t it time for something new? Think about it. Sandblasting leaves scars. Chemicals are messy. And bench grinding takes too long. But the Shipman Industrial Bolt & Pipe Cleaner changes all of that. Designed through years of professional shop and on-site experience, the Shipman is loaded with features that eliminate many of the hassles involved with this traditionally labor-intensive job. Plus its safer and faster. Best of all, each Shipman is manufactured by hand in the USA with rugged steel frames on castors and constructed with top quality parts for years of performance. Shipman even offers replacement brushes. It’s simply a machine whose time has come. After just one use, we think you’ll agree… the Shipman Industrial Bolt & Pipe Cleaner is one piece of equipment you shouldn’t be with out!

Tool Storage Products

Tool Chests and Tool Storage Tech Carts and Cabinets

Our new line of Modular chests consists of three versatile components which can be stacked in any combination of two or used independently. The chests are made entirely of 16 gauge (1.5mm) type 304 stainless steel, and are also available in powder coated steel with a choice of colors. These components are designed to meet a wide variety of needs in industrial and professional settings, either for secure storage or as sophisticated mobile workstations. Dimensions: 30″ W x 33.5″ H x 26″ D The TCTech cart is made entirely from 16 gauge type 304 stainless steel and is also available in powder coated steel. The Tech cart is constructed with heavy gauge pipe legs, and is designed to easily handle 500 lbs.

Specialty Machining Tools

Innovation is the foundation upon which H&S has built their worldwide reputation for total performance in service and products.

Special machining performance saves you time and money with:

1. advanced engineering that delivers peak performance on site or in the shop job after job.

2. precision machining and assembly provides maximum efficiency to accomplish your task faster and boost your production.

3. innovative blades, tool holders, cutters and accessories increase versatility and convert your standard H&S tool into a special machining workhorse making difficult beveling and machining projects routine.

The patent pending Multi-Prep® is a classic example. Call us with your toughest application. H&S special machining will help you be more profitable and more effective.

The ultimate in time saving efficiency, this patented Multi-Prep® cutter will simultaneously clean the tube O.D. or remove membranes and place a clean, accurate bevel on the end. They are generally used our model BR or MB tools. The Multi-Prep® cutter increases efficiency dramatically.

More about the Multi-Prep® cutter

Wear resistant coatings can now be removed with our exclusive cutter. Replaceable carbide inserts accurately clean cladding for welding. Fully clad and one-sided cladding can both be accomplished. The single side removes the overlay without damaging the other side.

Stub removal from headers is simple with the model MS and tool holders sized to your tube dimensions.

Profile beveling automatically matches the tube end contour to the radius of the piece to which it will welded. Contact the factory with your specifications.

Hydro Test Pumps

Downloads:

|

Diaphragm Series Test Pumps

|

|

Piston/Roller Series Test Pumps

|

|

Electric Series Test Pumps

|

|

High Pressure Pneumatic Series Test Pumps

|

|

High Pressure Plunger Series Test Pumps

|

|

Fire Hose Tester Series Test Pumps

|

|

Accessories for Test Pumps

|

Weld Test Plugs

Downloads:

HYPUR-MATE Weld Testers

- Patented multi-schedule seal design 1

- Standard range from ½” to 24” 2

- Rapid hydraulic actuation from 4” upwards 3

- Significant savings on shutdown time

- Suitable for fluid & and gas test mediums

- Simple, cost effective, reliable hydrostatic testing

- Minimal test medium required

- Standard pressure rating to ANSI 2500

Turnkey Welding Services/Project Management

VALVE SERVICES

Main Steam Isolation Valves

Gate Valves

Globe Valves

Check & Stop Valves

Valve Replacement Services

PUMP SERVICES

Pump Replacement

Pump Body and Shaft Overlays/Repairs

Re-Machining Services

REACTOR VESSEL & RPV HEAD REPAIRS

RPV Flange Repair / Resurfacing

RPV Nozzle Safe End and Weld Overlays

Primary Piping Overlays / Repairs

Emerget Repair, Hot and Cold Leg

Preemptive Weld Overlay for RPV Nozzles

STEAM GENERATOR REPAIRS

S/G Feed Ring Repairs

Feedwater/Aux Feedwater Nozzle Repairs & Replacements

REACTOR COOLANT PUMP REPAIRS

Stub and Bolt Hole Repairs

REACTOR COOLANT SYSTEM PIPING

PWSCC/IGSCC Weld Overlays/Repairs

Pipe Replacement

Pipe ID/OD Overlay

SECONDARY PLANT SYSYTEM REPAIRS/REPLACEMENTS

Pipe Replacement

Extraction Steam Piping

Replacements/Overlays

Service Water System Piping Overlays / Strainer Repairs & Replacements

Piping ID/OD Overlay

MSR Internal Replacement

MSR Retubing

Heat Exchanger Upgrades/Change-Outs

Large Bore Pipe Cladding

Pump Shaft Repairs

L/P Turbine Inner Casing Repair

Dry Fuel Storage Support/Canister Welding

On-site heat treatment

Heat Exchanger Tools and Condenser Tools

Downloads:

Quality Tube Tools For An “I Need It Yesterday” World.

As the original tube tool company since 1892, you can count on Elliott Tool Technologies for high-quality products that are available when you need them.

Boiler and Heat Exchanger and Cleaning products

Downloads:

- 888-Descale

- Product-List-Descalers.pdf

- DPG-Product-List.pdf

- Solutions.pdf

- Product-List-Solutions.pdf

The unique safety features of Delta’s 888 DESCALE let our innovative technology remove all stubborn fouling deposits right down to the bare metal. Safely dissolves most calcium scale and rust deposits from water-operated systems. Simply introduce the recommended quantities of Delta 888 DESCALE into a circulating loop flowing from bottom to top of units. Eliminate system bleed-off and chemical treatments during cleanings. Watch for excessive foaming and add Delta 888 DESCALE slowly. Entire tower systems may be cleaned online by adding our PS 8000. Most cleanings finished within 2-4 hours or when solution stops foaming. Overnight soak is possible. Our descalers may be added directly to pre-treated systems and may be disposed down regular sewers with water. This is our most universal descaler and can be adapted to successfully clean most any fouled equipment or systems. Please contact a local rep or our office for additional, helpful information on our many capabilities

Additional 888 Descale benefits.

Environmentally Friendly

• Non-Toxic, Non-Hazardous, Biodegradable

• No Compatibility or Waste Disposal Issues

Safe to Touch

• Safe Enough to Hold in the Open Hand

• There are NO Hazards to Your Equipment

Rapid Cleaning

• Most Cleanings Accomplished within Hours

• Overnight Soaking is Possible

Onsite Labor & Training

• Delta Professional Services Offered

• Onsite Supervision and Training Available

Energy Savings

• Considerable Energy Savings Annually

• Return on Investment in Just a Few Months

Areas of Application & More

• Pipes, Heat Exchangers and Condensers

• Cooling Towers, Chillers and Air Compressors

ARGWELD PURGE BLADDER SYSTEMS

ARGWELD® PURGE BLADDER SYSTEMS

Argweld® Inflatable Purge Bladders are the most effective systems available for pipe purging. The system is pulled into position and inert gas is used to inflate the bladders (dams) which provide a 100% airtight seal on either side of the weld joint, after which the pressure in the system opens the purge valve and the gas purges the space between the bladders ensuring a clean, even penetration bead. Once the weld is completed, the gas is turned off and the bladders are deflated so the system can be pulled through the pipe to the next weld. These systems are specifically designed to be easily pulled into position through long sections of pipe and around elbows without the risk of getting jammed or stuck in the pipe. This uniquely designed system has become an industry standard worldwide for applications involving stainless steel, chrome or other types of pipe that require an oxygen-free weld. The Argweld® systems are used extensively at LNG sites, refineries, power plants, food processing, pharmaceutical and fabrication facilities.

FEATURES

Compared to other methods of gas purging for pipe welding the Argweld® Purge Bladder systems have a number of

distinct advantages that lead to consistently clean welds and significant savings.

- Reliable. A good purge can be achieved and maintained every time without the fear of the dams becoming dislodged or compromised during the weld process.

- Faster. These systems are the fastest method of pipe purging by far with no time wasted building, taping or gluing dams in place, and no time wasted purging long sections of pipe. Due to their superior design, the purge time required is up to 8 times faster than foam, paper or other conventional purging methods. For example, an 8” pipe can be purged to less than 1% O2 in less than 60 seconds and a 12” pipe in about 90 seconds

- Use less inert gas. Argweld® purge systems also offer huge savings from reduced gas consumption for weld purging. They typically use less than 1/3 of the amount of gas required with other types of purge dams.

- Easy to use. Argweld® purge bladders greatly simplify the process of inert gas purging. With minimal training bright shiny welds that pass inspection can be achieved in no time.

More Details : Argweld 2012

Shipman Bolt and Pipe Cleaner & Industrial Socket Set

Its finally here, a portable, purpose built machine that uses a patented brush system to cleean even the dirtiest bolts and pipes – from 3/4” to 3” in diameter – faster, safer and cleaner than ever before. Developed through years of on-site and shop experience, the Shipman Industrial Bolt & Pipe Cleaner offers distinct advantages over traditional cleaning methods. Made in the USA, the Shipman Industrial Bolt & Pipe Cleaner takes the hard work out of a dirty job.

We’ve all been there. You know, standing in front of a screaming benchtop grinder with a dirty bolt or pipe – the sparks flying and your forearms aching from turning as you slowly erase the rust and sludge left behind by years of heavy use. Finally you finish, ignoring your sore back, stiff hands and raw skin covered with stinging, irritating metal filings. Then you pick up another piece and start all over again.

If this sounds all too familiar, don’t worry. You are not alone. Fact is no matter how you approach it, cleaning pipes and bolts has never been an easy job. The good news is that it doesn’t have to be that way any longer.

The Shipman Industrial Bolt & Pipe Cleaner takes the hard work out of a dirty job. Simply place any length of pipe or bolt into the machine’s powerful chuck and adjust the cleaning wheel diameter. Then flip the conveniently placed switch and guide the variable-speed power-assisted Servo Drive.

That’s it. Just watch as the Shipman’s patented brush system quickly and easily lifts years of grit and grime from even the dirtiest bolts or pipes and traps them in one small on-board collecting unit. Either way, there are no more bits of sharp metal on your clothes, your skin, or your eyes. Your left with an incredibly clean bolt or pipe that’s ready to coat or re-install. All in a fraction of the time it used to take!

Its finally here, a portable way to clean your studs, before you remove the nut. Just pull out the socket that fits the stud and attach the Shipman Socket to a low RPM ½ inch cordless or electric drill. For a safer cleaner way to maintenance studs, bolts and pipe, the one electric utility tool you can’t afford to be without. Made in OKLA. USA.

Custom Sizes

Custom Sizes are available for diameter and depth.

Please call for Custom Sizes at 709-726-3490.

We also have a way to clean the inside diameter with our new ID Tool, The ID tool can clean 4½ inch turbine nuts in 15 to 20 seconds each. Custom Diameters available. Please call for special orders.

Electronic Stud Measurement and Elongation Equipment

Downloads:

DAKOTA ULTRASONICS

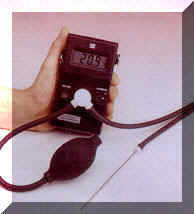

The MINI-MAX Bolt Tension Monitor

Ultrasonically measures the elongation produced by tightening a threaded fastener.

- The FIRST cost-effective ultrasonic solution available on the market.

- EFFECTIVELY monitor your bolts during periodic shutdowns over the service life of the fastener.

- VISUALLY compare the unloaded to the loaded waveform.

- MEASUREMENT QUANTITIES Time (nanoseconds), Elongation, Load, Stress, and Strain.

- DISPLAY OPTIONS — RF, Rectified, Large Digits with Limits Bar.

- DISPLAY RESOLUTION 1/8 inch VGA 240 x 160 pixels.

- STORES 8000 readings and waveforms in multiple groups.

- BUILT-IN linear regression or vector for optimizing load measurements.

- AUTO SET feature automatically optimizes detection and adjusts display.

- HI/LO ALARM tolerance limits work in conjunction with the data port and external pump shut-off device.

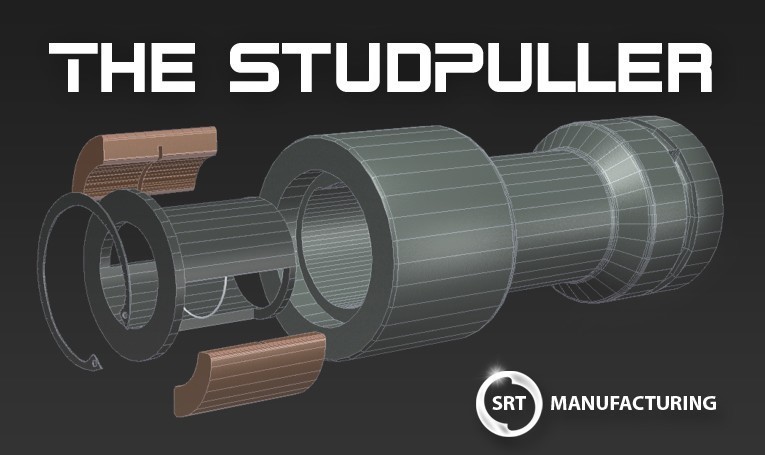

Stud Removal Tools

Downloads:

Operating & Instructions Manual

IMPORTANT SAFETY INFORMATION ENCLOSED

READ THIS ENTIRE MANUAL PRIOR TO OPERATING TOOL.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS AND INSTRUCTIONS COULD RESULT IN EQUIPMENT DAMAGE, SERIOUS INJURY OR POSSIBLY EVEN DEATH… PUT SAFETY FIRST!

WARNING:

- Always wear appropriate PPE while operating

- Impact powered tools vibrate in use. Vibration and repetitive motion may be harmful to arms and hands. Stop using tool if any discomfort, tingling feeling or other pain Seek medical advice prior to resuming use.

- Always turn off air supply and disconnect supply hose from impact prior to removing, installing or adjusting any component on this tool, or before performing any maintenance on this

- Keep hands, loose clothing and long hair away from thetool in rotational

- Tool will continue to rotate, unengaged, when impact throttle is

- Do not lubricate with flammable or volatile liquids such as kerosene or

- This tool is not insulated against electric

- This tool is not designed for work in explosive atmospheres.

- Anticipate sudden changes in motion during start-up operation of

- This tool can exert strong forces on the

WARNING:

The use of other than originally designed replacement parts may result in safety hazards, decreased tool performance, increased tool maintenance and may void all term warranties.

SRT Manufacturing is not responsible for customer’s modification of tools for applications on which SRT was not consulted. Repairs should only be made by authorized, trained personnel. Consult SRT Manufacturing for assistance.

It is the responsibility of the operator’s employer to place the information in this manual into the hands of the equipment operator.

The only tool that should be used to rotate the StudPuller is a properly inserted drive tool. Any other tools, such as a pipe wrench, will void the warranty and could permanently damage the StudPuller.